New Addition to the Fabrication Lab: Innovating with the Calibry 3D Scanner

Share This Article!

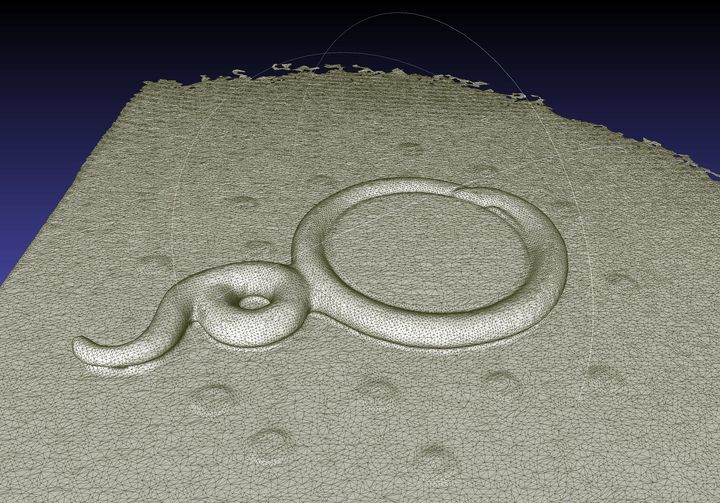

The Calibry 3D Scanner captures professional-grade scan quality results.

This handheld scanner is easy-to-use and suitable for a wide range of manufacturing, medical professionals, engineers, and designers. The system is designed to capture 3D scans of medium to large objects such as human faces, body parts, car engines, and large objects, including entire cars.

Some industry applications using 3D scanning are within the automotive and health care industries (orthopedics and prosthetics). The design industry also uses 3D scanning to help create sculptures that may have interesting and complex curvatures from an artistic perspective but a problem for the engineers to produce precisely. The 3D Scanner digitizes an object and produces a CAD file with precise measurements where the part can be then cut out using our CNC equipment.

Calibry scans objects into digital 3D models from 20 cm to 10 m in length. The accuracy of the Calibry is 0.1 mm and has a resolution of 0.3 mm. It has a touch screen to keep track of the data collected by the scanner.

The software collects the raw data from the scan and transforms it into a finished model. You can fill holes, simplify the mesh, apply texture, and much more. During the scanning, you can adjust texture brightness and regulate sensitivity parameters to capture difficult objects.

At the North Forge Fabrication Lab, we were fortunate to take the scanner through months of extensive testing before deciding on purchasing it. As a member of the North Forge Fabrication Lab, you will now have access to use the scanner as part of your membership. Training will be required before using the scanner, and North Forge staff will provide the training. The scanner will also be available to take off the premises so you can scan parts of your job site or business.

All of the testing articles at the Fabrication Lab can be found on Fabbaloo.